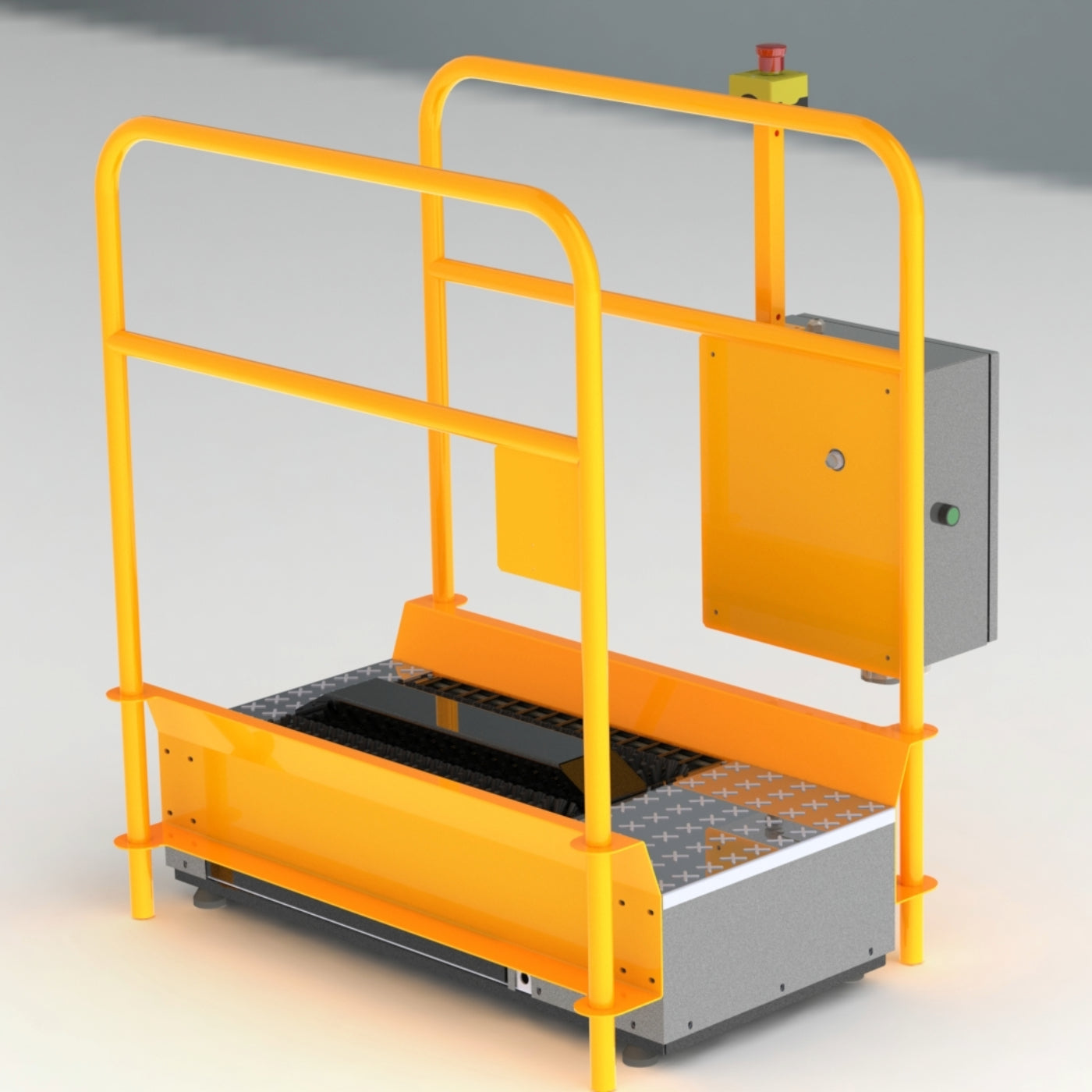

Boot Cleaner SC-02 | Automatic Dry Walkway

⠀

Click the button above and request your quote without hassle. The process is simple, takes less than 3 minutes and you receive a response within 1 business day. Speed up your purchases with fast, professional service focused on what your company needs.

⠀

⠀

Choose options

⠀

Click the button above and request your quote without hassle. The process is simple, takes less than 3 minutes and you receive a response within 1 business day. Speed up your purchases with fast, professional service focused on what your company needs.

⠀

⠀

⠀

Click the button above and request your quote without hassle. The process is simple, takes less than 3 minutes and you receive a response within 1 business day. Speed up your purchases with fast, professional service focused on what your company needs.

⠀

⠀

The SC-02 is the perfect choice for companies that need to remove different levels of dirt from shoes efficiently and quickly, without the use of water. Ideal for industrial environments with medium flow of people.

Overview

The Boot Cleaner SC-02 is a dry, automatic, and walkway sanitary barrier. In just 12 s, it removes dust and light residues from the soles as the employee walks, protecting production lines against contamination without using water or chemicals.

How It Works

When stepping on the platform, presence sensors activate the rotating brushes. On average 12 s later, the dirt is collected in the waste drawer and the equipment shuts off automatically, maintaining continuous flow without lines or manual activation.

Types of Dirt Removed

-

Dust and fine particles

-

Light residues (paper, plastic, sawdust)

-

Intermediate impurities that do not require water washing

Usage Indications

-

Manufacturing Industries – prevents dirt on the final line.

-

Warehouses & Logistics Centers – keeps storage areas clean.

-

Service Sector – receptions, common areas, and shipping.

Ideal for low to moderate flow where dry sanitization is sufficient.

Market Differentials

-

100% dry brushing – zero water consumption, no effluents.

-

Sensor automation – no pedals or push buttons.

-

Compact walkway – easily integrates with access controls.

-

Quick cycle (12 s) – does not create bottlenecks at the entrance.

Maintenance and Durability

-

Construction in painted carbon steel or 304 stainless.

-

Quick-change brushes; removable waste drawer.

-

WEG gearmotor: long service life and low maintenance.

Operational Efficiency and Savings

-

No water ⇒ reduces utility costs.

-

Plug-and-play installation: only one power outlet.

-

Maintains people flow without interruptions.

Safety and Compliance

-

Emergency push button for immediate stop.

-

Protective covers against moving parts.

-

Design in compliance with NR-12.

Conclusion

The Boot Cleaner SC-02 delivers fast, automatic, and economical sanitization for low to medium-flow environments.

Want to protect your process without complications? Request a quote and discover how the SC-02 adapts to your operation.

POWER SUPPLY

- Voltage: 220V

- Frequency: 50/60Hz

- Power: 2200W

MOTORS AND CONTROL

- Motors: Three-phase gear motor

- Motor Power: 0.75HP / 0.55kW

- Number of Poles: 4 poles

- Motor Speed: 1665 rpm

- Gear Reducer: Ratio 20:1

- Output Speed: Approximately 83.25 rpm

- Speed Control: Via WEG frequency inverter

Inverter Protection Functions (WEG CFW300):

- Overcurrent: Shuts off if current exceeds safe limit

- Thermal Overload: Monitors current and time to avoid excessive heating

- Temperature Protection via PTC/Thermistor: Stops operation if critical temperature is reached

HYGIENIZATION SYSTEM

- Method: Dry brushing of shoe soles

- Brush Type: Virgin nylon, 1.00 mm diameter per bristle

- Replacement System: Quick-change system, making maintenance easier

- Average Hygiene Time per Person: 10 seconds

- Capacity: Approximately 6 people/minute / 360 people/hour

CONTROL PANELS

- Electrical Panel: Present in all versions

- Hydraulic Panel: Not available (dry sanitization)

SENSORS AND AUTOMATION

- Activation: Automatic via presence sensor

- Control: Via digital signal

- Timer: Adjustable for customization of operation time

DIMENSIONS AND WEIGHT

- Equipment Weight: 90kg

- Dimensions: [As per technical sheet]

STRUCTURE AND CONSTRUCTION

- Material: Carbon steel with electrostatic painting or AISI 304 stainless steel

- Finish: Robust structure with protective housing, suitable for industrial environments

BRUSHES:

- Bristle Material: Virgin nylon

- Bristle Diameter: 1.00 mm

- Lifespan: Approximately 4 years

- Replacement System: Quick replacement, no tools required

WASTE SYSTEMS

- Waste Drawer: Removable drawer for waste collection

- Compartment Dimensions:

- Height: 27mm

- Length: 427mm

- Width: 590mm

- Compartment Volume: Approximately 6.8 liters

- Disposal Procedure: Remove the drawer using the provided handles, discard waste according to type, and replace the drawer

CERTIFICATIONS AND STANDARDS

- Certification: Regulatory Standard NR12 (Compliance with safety standards)

WARRANTY

- Warranty Period: 12 months (National product)

SAFETY

- Emergency Button: Present

- Brush Protection: Protective grid in the brush area

Download Center

Here you can quickly access and download essential documents for your equipment. Choose the desired content below:

Didn’t find what you needed? If you need other technical documents, contact our engineering team via WhatsApp.

Trusted by companies from all sectors around the world

Quick and efficient cleaning for industrial environments

Waterless sanitization

Designed for environments with medium foot traffic, the SC-02 removes dirt such as dust, debris, and heavy residues from shoe soles quickly and automatically. The dry brushing technology eliminates the need for water, making it perfect for places where water use is not viable or necessary. With just 4 seconds per sanitization cycle, it provides continuous and agile operation, ideal for factory entrances and production zones.

Full control over your shoe sanitization

Smart adaptation

Every industry has its own particularities, and the SC-02 is ready to meet them all. Available in two material options — AISI 304 stainless steel for high-humidity or strict sanitary environments, and carbon steel with electrostatic painting for conventional environments — the SC-02 adapts perfectly to your context. In addition, its integration capability with our access control systems makes it even more versatile to meet your company’s specific demands.

SIMPLE INSTALLATION AND INTUITIVE OPERATION

Quick implementation

The SC-02 was designed to make your life easier. Without the need for complex infrastructure, it requires only one power point to start operating. Its design allows it to be easily relocated as environmental needs change. The automatic sensor activation ensures intuitive operation, while the automatic shutoff after each cleaning cycle optimizes energy consumption and extends the equipment’s lifespan.

standards met

We help your company comply with HACCP, preventing contamination and standardizing sanitization.

The automation and sanitary control of our products contribute to the safety required by FSSC 22000.

Our solutions help ensure compliance with ISO/22000, guaranteeing hygiene and food safety.

Guaranteed efficiency

COST-BENEFIT

The SC-02 offers efficient dry sanitization, with a simplified structure that ensures excellent performance for a lower investment. It is an ideal solution for companies looking to optimize costs without sacrificing quality. Combining robustness and ease of maintenance, the SC-02 delivers high added value, becoming an attractive option for businesses of all sizes that value efficiency and savings.

our product, tested in

practice

READY TO CUSTOMIZE THE SC-04 FOR YOUR COMPANY?

Less downtime, more productivity

We know that time is money. That’s why the SC-02 was built with high-quality materials and reliable components, such as WEG three-phase gear motors. Its replaceable brushes with an easy-change system and removable waste drawer make maintenance simple and quick. This means less machine downtime and more focus on what really matters: your production.

por que a SC-02 é a escolha certa para sua empresa?

⠀

APPLICATION VERSATILITY

Suitable for various industrial sectors, the SC-02 is the perfect intermediate solution for companies that need efficiency without compromising robustness.

EFFICIENCY IN medium-traffic

With a cleaning time of just 12 seconds per user, the SC-02 maintains people flow without compromising sanitization, ideal for operations that cannot stop.

ECONOMICAL DRY SANITIZATION

Eliminate the need for water in the sanitization process, reducing operational costs and contributing to environmental sustainability

Questions

Here we have gathered the main questions about the product and their answers.

Features and Applications

The SC-02 is recommended for industrial environments with high foot traffic, such as factories, warehouses, production areas, and facility entrances where it is crucial to prevent contaminants from entering through shoe soles.

The SC-02 is effective in removing light to intermediate dirt, such as dust, debris, and particles stuck to shoe soles, without the need for water.

Yes, especially in the version made of AISI 304 stainless steel, which offers greater corrosion resistance and is suitable for outdoor or high-humidity environments.

Customization and Configuration

Yes, the SC-02 can be customized according to your company’s needs, including material options (stainless steel or carbon steel with electrostatic painting) and integration with our access control systems.

Yes, the brush rotation speed is adjustable. You can set the speed according to the level of dirt that needs to be removed, optimizing the sanitization process.

The average sanitization time is approximately 4 seconds per user, but this may vary depending on the level of dirt and the type of sanitization chosen.

The SC-02 is equipped with presence sensors that automatically activate the equipment when the user steps onto the platform. After sanitization, the equipment automatically shuts off, saving energy and increasing service life.

Installation and Maintenance

No, the SC-02 only requires one electrical outlet to operate. There is no need for hydraulic connections, as the sanitization process is dry, making installation easier in different locations.

Maintenance is simple and practical. The brushes are easily replaceable without the need for special tools, and the waste drawer can be removed for regular cleaning. It is recommended to follow the manual instructions for inspections and periodic maintenance.

The waste drawer is designed to handle dirt accumulation throughout the day. The emptying frequency depends on traffic volume and dirt levels, but in general, it is easy to remove and clean.

Safety and Standards

Yes, the SC-02 complies with Regulatory Standard NR12, ensuring that it meets the safety requirements for user protection.

The SC-02 has safety devices such as an easily accessible emergency stop button and sensors that prevent unexpected activations. In addition, moving parts are protected by covers to prevent accidental contact. It is important that users follow the instructions and that the equipment is operated according to the manual guidelines.