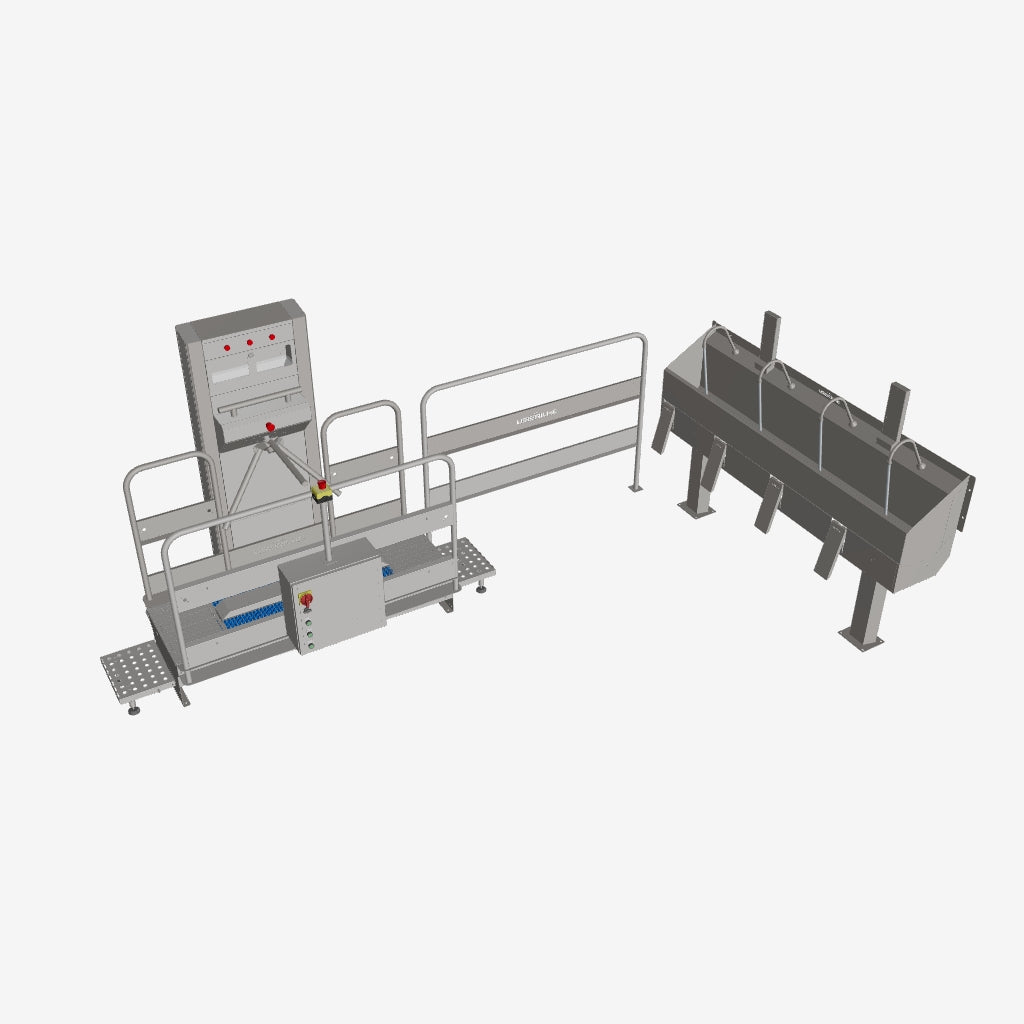

Sanitary Barrier | BS-02

⠀

Click the button above and request your proposal without hassle. The process is simple, takes less than 3 minutes and you receive a reply within 1 business day. Speed up your purchases with fast, professional service focused on what your company needs.

Each system component can be adapted to your operational flow, offering a practical and efficient solution for your production environment challenges.

⠀

⠀

Choose options

⠀

Click the button above and request your proposal without hassle. The process is simple, takes less than 3 minutes and you receive a reply within 1 business day. Speed up your purchases with fast, professional service focused on what your company needs.

Each system component can be adapted to your operational flow, offering a practical and efficient solution for your production environment challenges.

⠀

⠀

⠀

Click the button above and request your proposal without hassle. The process is simple, takes less than 3 minutes and you receive a reply within 1 business day. Speed up your purchases with fast, professional service focused on what your company needs.

Each system component can be adapted to your operational flow, offering a practical and efficient solution for your production environment challenges.

⠀

⠀

The BS-02 goes beyond simple sanitization, integrating access control, sole cleaning, and hand washing into a single efficient system.

Overview

The BS-02 is an industrial sanitary barrier that integrates sole sanitization, access control with automatic soap dosing, and high-performance industrial sinks. Designed for environments requiring strict sanitary standards — such as food industries, pharmaceuticals, and hospitals — the system offers an efficient and safe solution to prevent cross-contamination. Its robust construction in AISI 304 stainless steel ensures durability and compliance with the most demanding standards, including FSSC and ISO 22000.

How It Works

The sanitization process is automated and intuitive:

- The employee begins passage through the SC-05, where shoes are sanitized with rotating brushes and, if necessary, sanitizer spraying.

- Next, when approaching the BS-02 Turnstile, the system automatically dispenses soap onto the hands, granting access only after this step.

- Finally, the employee proceeds to the Vanguard sink to complete handwashing, using knee-operated faucets, ensuring touch-free sanitization.

Usage Indications

The BS-02 is recommended for companies requiring strict contamination control:

- Food and Beverage Industries: Contamination prevention during processing.

- Pharmaceutical Industries and Laboratories: Maintenance of sterile environments.

- Hospitals and Clinics: Access control to critical areas such as ICUs and surgical centers.

- Cosmetic and Chemical Industries: Protection against external contaminants in sensitive processes.

Market Differentials

- Integrated Solution: Components (SC-05, BS-02, Vanguard sink) work as a single system.

- Full Modularity: Allows adaptation to company layout, facilitating installation and maintenance.

- Exclusive Technical Documentation: Integrated electrical diagrams and personalized support.

- Complete Customization: Configuration for different shoe types, sanitization (dry or with water), and flow direction (entry and exit).

Maintenance and Durability

Built in AISI 304 stainless steel, the BS-02 resists corrosion and adverse industrial conditions. Components such as SC-05 brushes and BS-02 sensors are easily accessible and replaceable, reducing maintenance costs and extending equipment life. Preventive maintenance is simplified by the personalized documentation that comes with the product.

Operational Efficiency and Savings

- Optimized Flow: Automated process that reduces sanitization time and maintains high productivity.

- Efficient Resource Use: Saves water and sanitizers, thanks to precise dosing and automatic activation.

- Complete Integration: Minimizes operational failures and simplifies sanitary control, saving time and costs in the long term.

Conclusion

The BS-02 is the ideal solution for companies seeking efficient sanitary control, safety, and compliance with standards. With full modularity, complete customization, and high-level technical integration, the system protects your production and employee safety. Invest in a product that goes beyond basic sanitization, bringing operational efficiency and peace of mind to your industry.

Electrical Supply

- Voltage: 220V

- Frequency: 50/60Hz

- Total Power: 2900W

- Electrical Control: 24V with No-break system (internal battery) to keep the turnstile operating during power outages

Motors and Control

- Motors: 2 three-phase gear motors (for SC-05 brushes)

- Motor Power: 0.75HP / 0.55KW

- Number of Poles: 4 poles

- Speed Control: Frequency inverter (WEG brand) to adjust brush speed

Sanitization System

- Sole Sanitization (SC-05):

- Access Control (BS-02):

- Hand Washing (Vanguard):

Control Panels and Automation

- Electrical Panel: Present in all versions, with IP54 protection

- Hydraulic Panel: Optional, available for water-use configurations

- Sensors and Automation:

Water Supply and Consumption

- Water Inlet: ½-inch three-way ball valve

- Water Consumption:

- Sewage System: Direct connection to the client’s sewage system

Dimensions and Weight

- Total System Weight: Approximately 375 kg

- Total Dimensions: Dimensions may vary depending on the client’s custom configuration

Structure and Construction

- Material: AISI 304 stainless steel with thickness between 2mm and 3mm

- Finish:

- Brushes (SC-05):

Waste and Sewage Systems

- Waste Drawers (SC-05): Available depending on configuration

- Drainage System: 2 ½-inch piping for water drainage

Certifications and Standards

- Regulatory Standard NR12: Compliance with industrial safety standards

- Good Manufacturing Practices (GMP): Meets sanitary requirements for pharmaceutical and food industries

- Protection Rating: IP54 (protection against dust and water splashes)

Warranty

- Warranty Period: 12 months (National product with specialized technical support)

Download Center

Here you can quickly access and download essential documents for your equipment. Choose the desired content below:

Didn’t find what you needed? If you need other technical documents, contact our engineering team via WhatsApp.

our solutions, approved by the biggest companies around the world.

step 1

Sole sanitization

When entering the sanitary barrier, footwear passes through the SC-05, equipment that automatically cleans the soles with high-performance rotating brushes and sanitizer jets. This process removes dirt such as mud, oil, and dust, as well as eliminating bacteria and other microorganisms.

The SC-05 is activated by presence sensors, ensuring that the user does not need to touch anything to start cleaning. The equipment is designed to keep people flow fast and efficient, without causing lines or delays.

step 2

hand sanitization

The BS-01 Turnstile ensures that no employee enters controlled areas without going through the sanitization process. Before granting access, the turnstile automatically dispenses soap into the user’s hands, forcing them to move to the sink and complete washing.

This smart system prevents failures in hygiene protocols, ensuring all procedures are followed correctly. Additionally, the turnstile includes a no-break system, keeping access control active even in case of a power outage.

step 3

Water washing

After soap is dispensed by the turnstile, employees proceed to the Vanguard Sink to complete sanitization. With knee activation, the equipment releases water without manual contact, ensuring maximum safety against cross-contamination.

Made of AISI 304 stainless steel, Vanguard is durable, easy to clean, and designed to withstand constant use in industrial environments. Its sanitary design with rounded corners prevents dirt buildup, making it ideal for food, pharmaceutical, and hospital industries.

More than basic hygiene

Hygiene in Every Step

The BS-02 goes beyond simple sanitization, integrating access control, sole cleaning, and hand washing into a single efficient system. This solution reduces the risk of contamination, speeds up processes, and ensures your company meets the highest sanitary standards without compromising productivity.

a little more about our product

gallery

More than Equipment, an Integrated Solution

market differential

The BS-02 is not just the sum of different sanitization equipment. It is an integrated solution, designed to function as a single system, with exclusive documentation, electrical diagrams, and modules that perfectly adapt to your operation.

a little more about the

benefits

Added Value

The sanitary barriers offer modularity and complete integration, with exclusive documentation and simplified installation.

Operational Efficiency

The equipment streamlines workflow with an automated process that reduces sanitization time.

Standards Compliance

Our equipment complies with major sanitary standards and can be customized for different layouts and needs.

Questions

Here we have gathered the main questions about the product and their answers.

Usage and Applications

BS-02 is ideal for food, pharmaceutical, hospital, and laboratory industries, as well as other environments requiring strict contamination control. It is especially useful in high-traffic areas, such as entrances to production areas and cleanrooms.

Yes, we can adapt it to work in both directions (clockwise and counterclockwise). This way, you can configure one unit for entry and another for exit, ensuring complete sanitary control.

The BS-02 can sanitize safety boots and industrial footwear in general.

Is sole sanitization done with water or dry?

Sanitization can be customized according to your company’s needs. The equipment can be configured for:

- Dry sanitization, using only sanitizer misting, without wetting the footwear.

- Deep cleaning, with water and intensive brushing to remove heavy dirt such as mud, oil, and dust.

The BS-02 is a sanitary barrier that integrates sole cleaning, automatic soap dispensing, and hand washing into a single efficient system, ensuring safety and sanitary control in industrial environments.

Customization and Configuration

Yes! All customization capabilities of individual equipment (SC-05, BS-01, and Vanguard) also apply to BS-02. We adapt the system according to the needs provided in the configurator, which you can access by clicking "Request Quote".

No. The equipment is fully modular and can be adjusted to suit the layout and workflow of your operation.

Standards and Compliance

Yes! The product complies with standards such as NR12, Good Manufacturing Practices (GMP), and other applicable regulations, ensuring full compliance during audits and inspections.

Yes. The sanitary barrier comes with customized technical documentation updated according to the integration of the equipment, including electrical and hydraulic diagrams.

The BS-02 includes emergency stops, presence sensors, touchless activation, and a no-break system, ensuring operational safety even during power outages.

Quotes and Support

Click the "Request Quote" button on this page and fill out the configurator with your operation details. Our team will adjust the product to meet your specific needs.

Our team will contact you within 24 hours with a customized proposal for your company.