Choose according to your needs, see our

solutions

adopted by the largest industries

we follow the Global Hygiene Standard

Our equipment has become the standard in major multinational industries, implemented in operations that require strict sanitary control. Leading companies trust our solutions to ensure efficient hygiene processes aligned with the sector’s most demanding regulations.

our solutions, approved by the largest companies worldwide.

Complete Solutions for Industrial Hygiene

What Are Clean Line Barriers?

Sanitary barriers are systems designed to structure and standardize hygiene control in productive environments. They combine different equipment into a single organized flow, ensuring each hygiene step is completed efficiently before access to controlled areas.

Unlike standalone equipment, sanitary barriers are complete and configurable solutions, tailored to each operation’s needs. They enable more precise hygiene control and reduce process failures, becoming an essential element for sanitary safety and compliance.

Each Step Designed for Maximum Efficiency

How Do They Work?

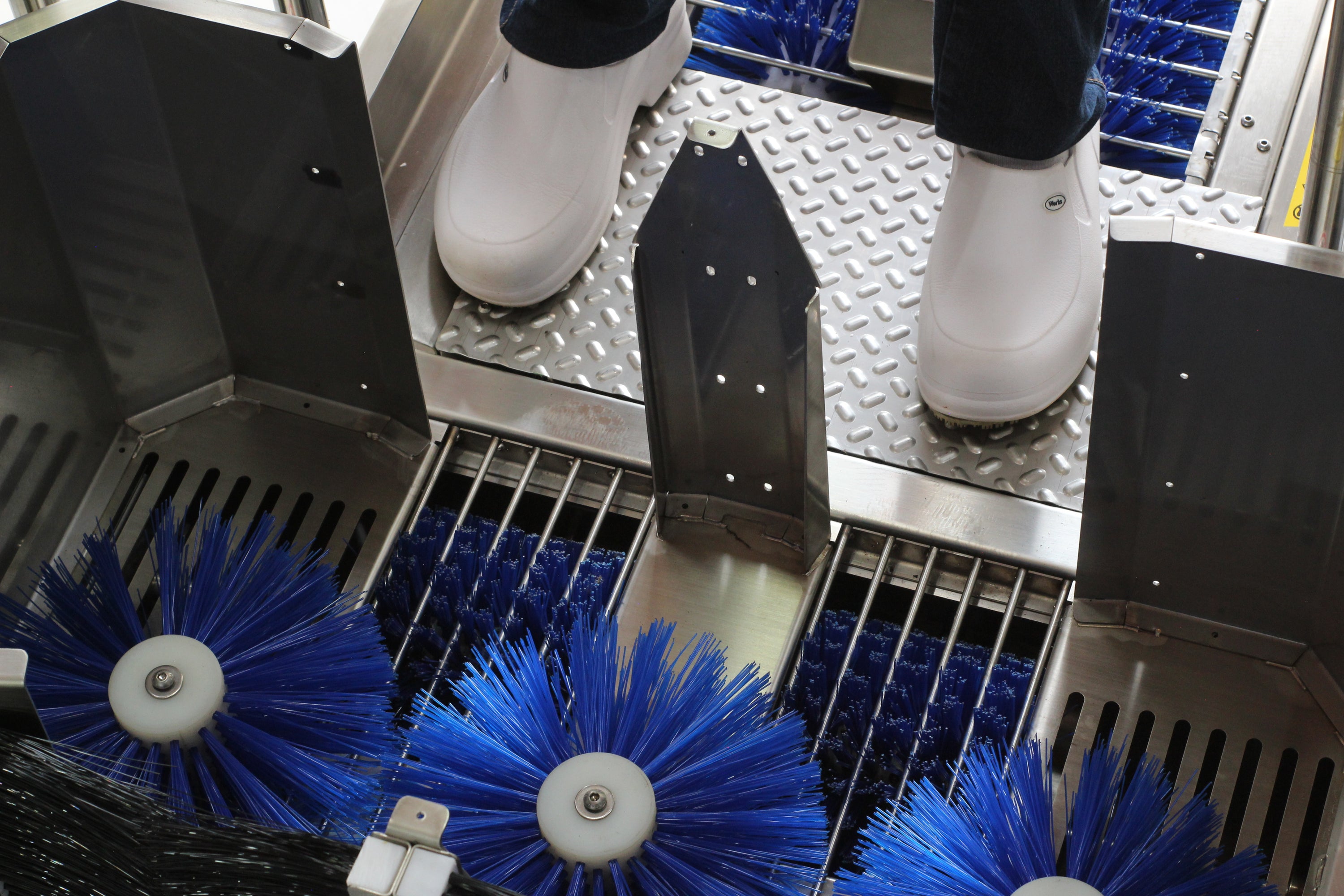

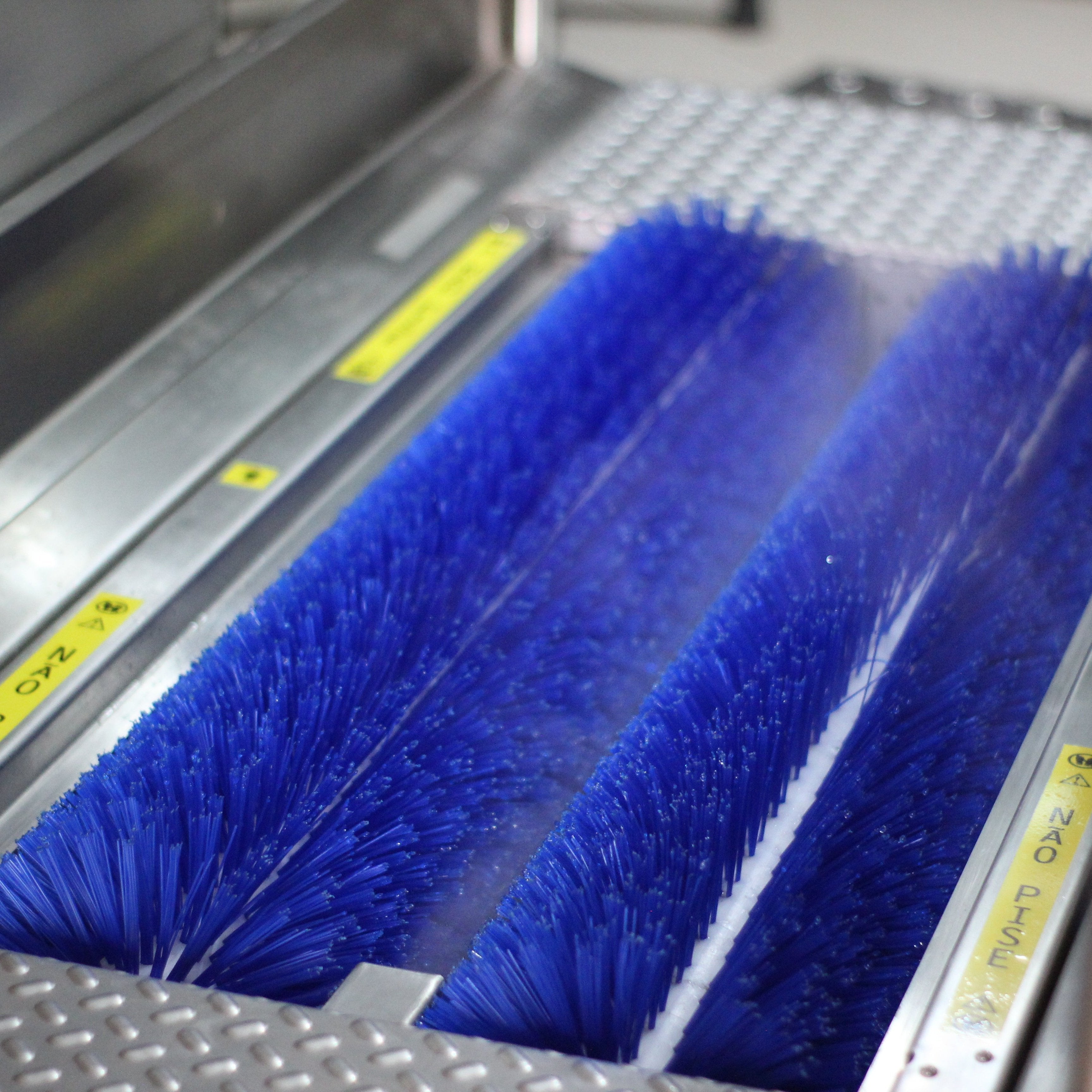

Sanitary barriers ensure that each person goes through the necessary hygiene steps before accessing productive environments. The process may include cleaning shoe soles, hand sanitization, and access control, preventing the entry of anyone who has not followed the correct protocol.

Each barrier is configured according to site requirements, using different hygiene methods. While some environments require only sole cleaning, others need a more complete system, including disinfection with specific products and validation of the process before granting access.

Indispensable for Sectors Operating with High Sanitary Standards

Who Are They For?

Sanitary barriers are used in industries and operations where strict hygiene is essential for process safety. They are applied in productive environments where any sanitary control failure could compromise product quality and regulatory compliance.

Companies in the food, pharmaceutical, healthcare, and logistics sectors adopt sanitary barriers to ensure everyone accessing controlled areas follows the required hygiene protocols. In addition to meeting regulatory requirements, barriers structure and standardize hygiene efficiently, reducing risks and preventing operational interruptions.

Compliance with the Highest Sanitary Standards

Meeting Industry Requirements

Our sanitary barriers are designed to meet the strictest hygiene and safety standards. All equipment includes safety reports, complete technical documentation, and follows internationally recognized standards.

added value in your operation

our differentiators

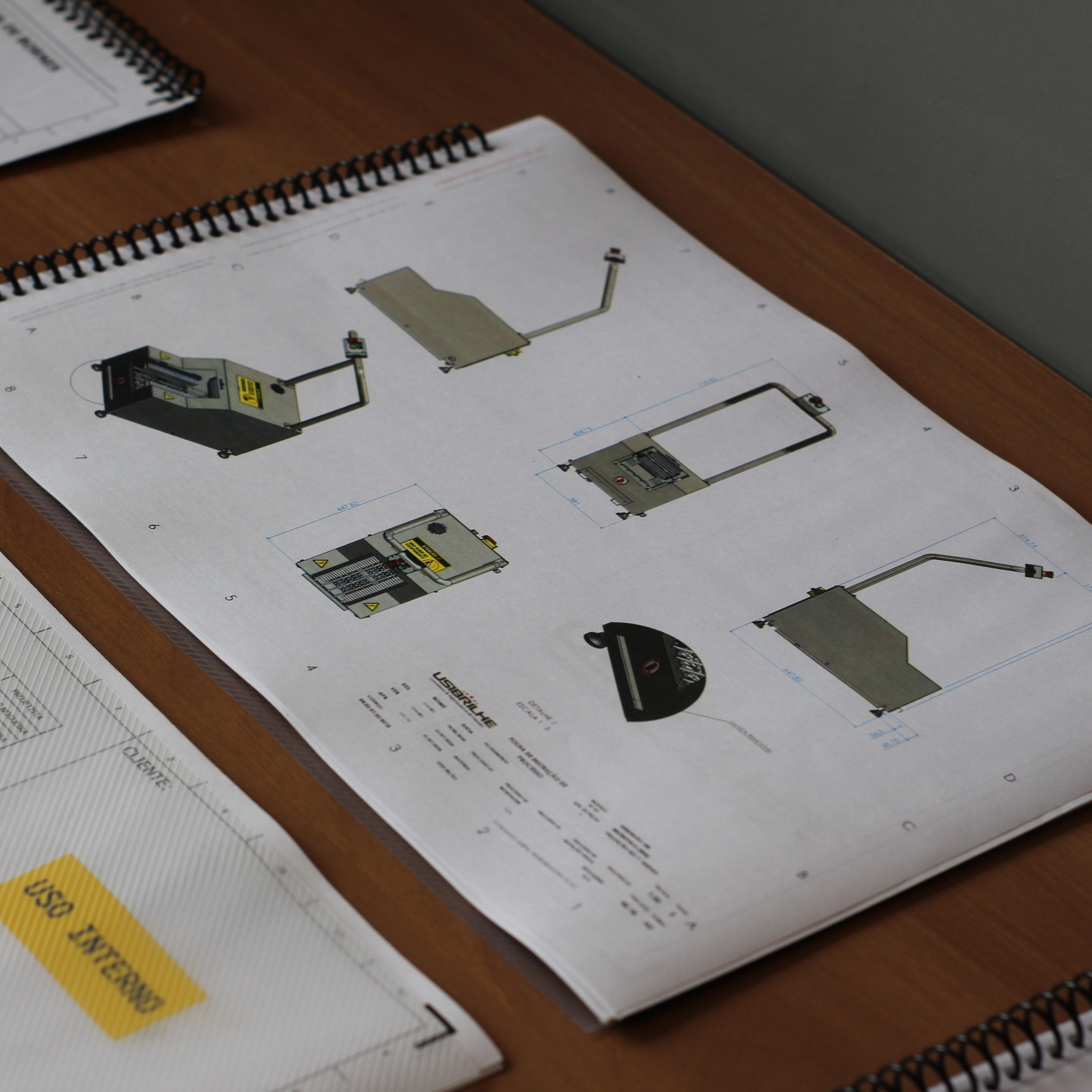

Technical Documentation

Each piece of equipment comes with electrical diagrams, mechanical drawings, and parts lists, making installation, maintenance, and integration with other systems easier. Documentation is always available for reference.

standards met

Our sanitary barriers comply with major industrial standards, including NR12, ensuring safety and compliance with audits and inspections.

Continuous Support

We offer spare parts and specialized technical support, ensuring your equipment operates at maximum efficiency. Our structure allows for quick replacements and technical assistance whenever needed.

see below an example of a sanitary barrier

our products, tested in practice

success stories

Shoe contamination was reduced by 98% with Usibrilhe solutions

Nestlé adopted Usibrilhe products as standard in its Brazilian units due to our quality.

Questions

Here we have gathered the main product questions and answers.

General Concept

A sanitary barrier is a structured system that integrates different hygiene equipment, such as sole cleaning, access control, and hand sanitization, to ensure sanitary safety in high-risk areas such as industries, hospitals, and logistics centers.

It ensures compliance with sanitary standards, prevents contaminants from entering controlled environments, and organizes hygiene processes, ensuring safety and operational efficiency.

Sanitary barriers are complete, integrated solutions, while other solutions may address only one aspect, such as sole cleaning or hand sanitization. A sanitary barrier combines several processes, such as sole cleaning, hand sanitization, and access control, creating an efficient and standardized flow that reduces risks and fully meets regulatory requirements.

Quotation and Customization Process

The quotation process starts with identifying the customer’s needs, such as people flow, required hygiene type, and available space. After filling out the budget request form, our team will present a personalized solution tailored to your specific demands.

Sanitary barriers are configured according to the customer’s space and specific needs. Customization may involve selecting sole cleaning equipment, turnstiles, sinks, and more, depending on people flow and applicable standards.

The price of a customized sanitary barrier depends on several factors, such as people flow, required equipment (turnstiles, sinks, etc.), and the specific configuration of the solution. After filling out the quotation form, our team analyzes your needs and provides a detailed budget based on the chosen options.

Support and Documentation

Each piece of equipment comes with complete technical documentation, including electrical diagrams, mechanical drawings, and spare parts lists, ensuring full transparency and traceability. These documents are available to support audits and operational needs.

Yes, we provide ongoing support to ensure your equipment always works efficiently. In addition, we have spare parts available if needed.

Due to the nature of the product, these documents will only be sent after purchase. However, our engineering team is available to provide files with general measurements, top views in DXF format, and more. For further information, contact our team via email falecom@usibrilhe.com.br.

Sanitary Barrier Applications

A escolha da barreira ideal depende das necessidades específicas da sua operação, como o número de pessoas, o tipo de indústria, e os requisitos de higienização. Nosso time pode orientar sobre a solução mais eficiente durante o processo de cotação.

Sanitary barriers solve contamination control issues, ensuring only sanitized individuals enter sensitive areas, and help meet sanitary standards, preventing health and safety risks in production processes.

In addition to ensuring compliance with sanitary standards, sanitary barriers provide enhanced safety, reduced human error in hygiene processes, and operational efficiency. They minimize cross-contamination risks and ensure safety protocols are strictly followed without compromising productivity.